Introduction

Silicon PU aims to offer players a superior and safe sports field.Silicone PU is a new generation of sport surfaces material, efficiently slove problems which PU can not fullfill. Compare to PU, silicone PU have a longer lifetime, easy to maintenance. It is a two-component liquid material that makes the construction process easier and shorter time when compared with the traditional PU (polyurethane) material.

Application

Basketball Court

Tennis Court

Badminton Court

Voleyballl Court

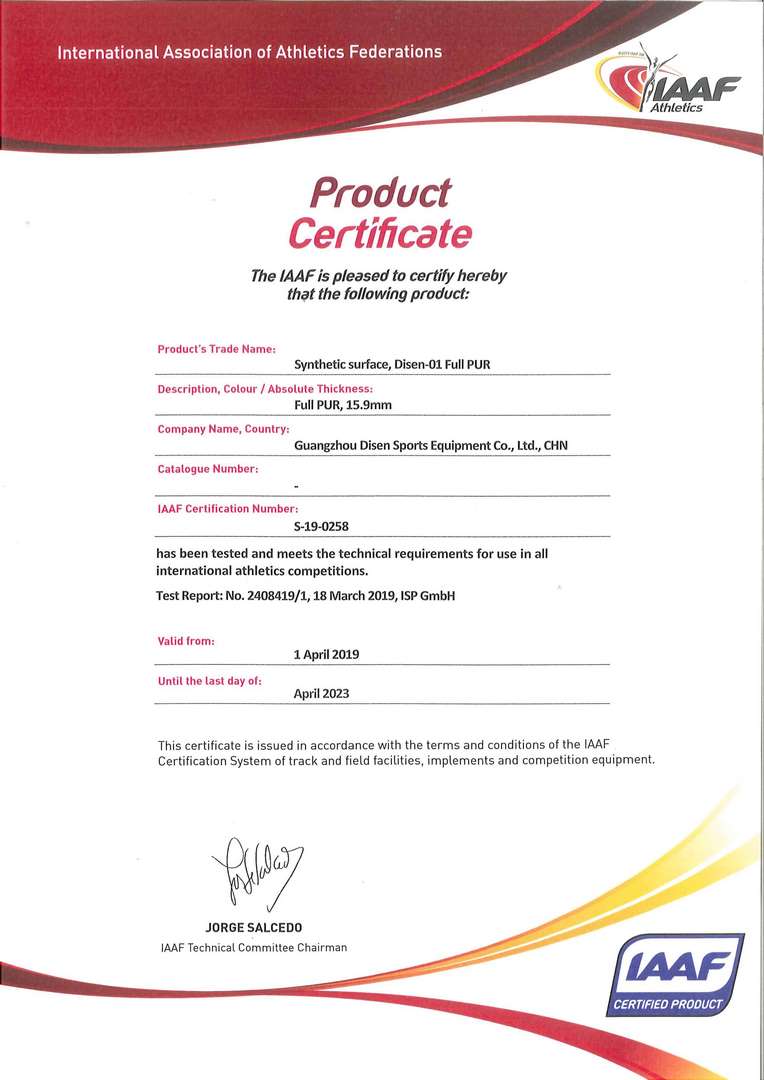

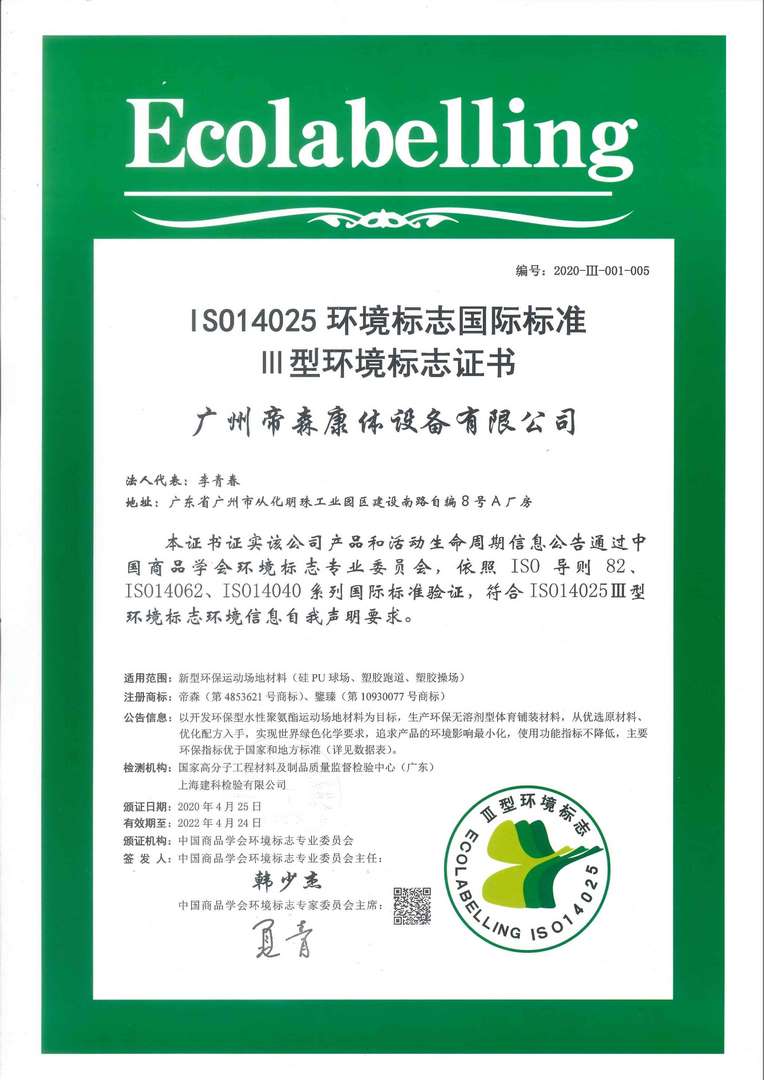

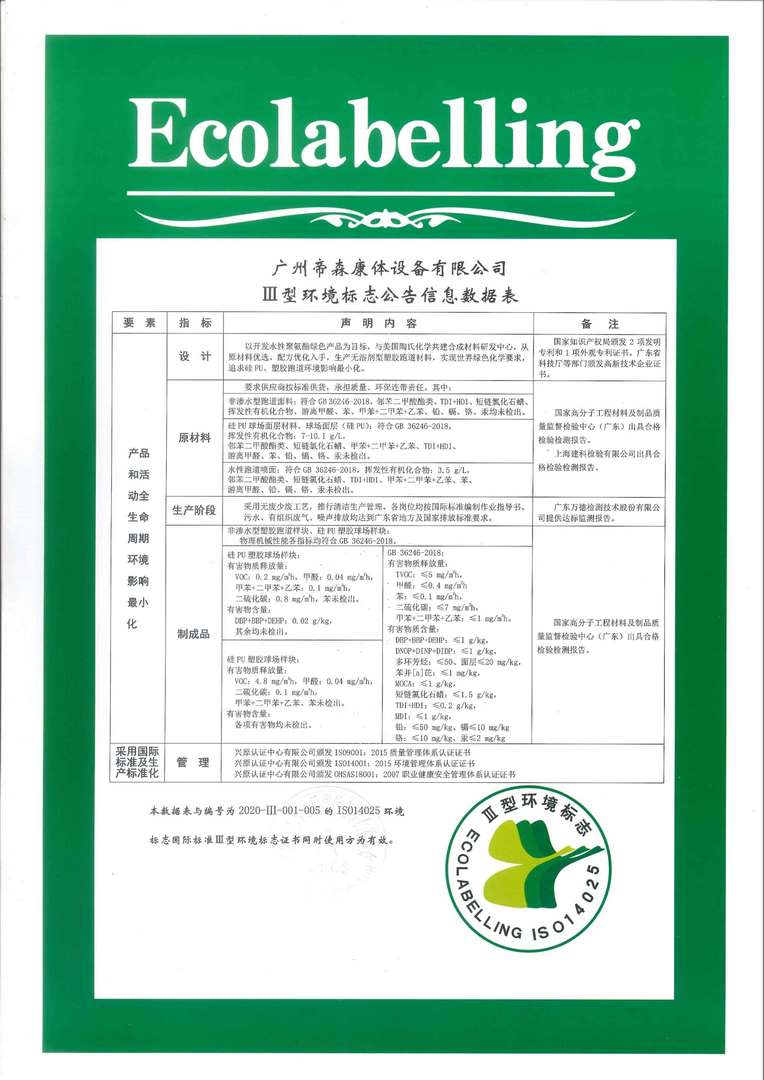

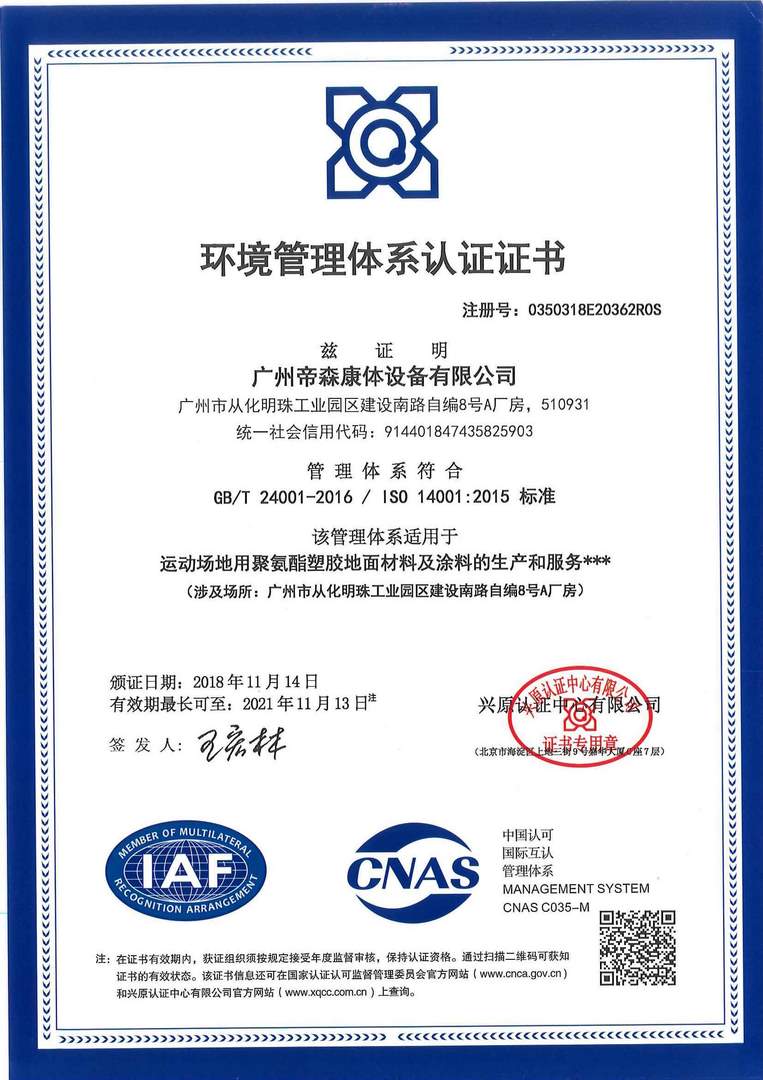

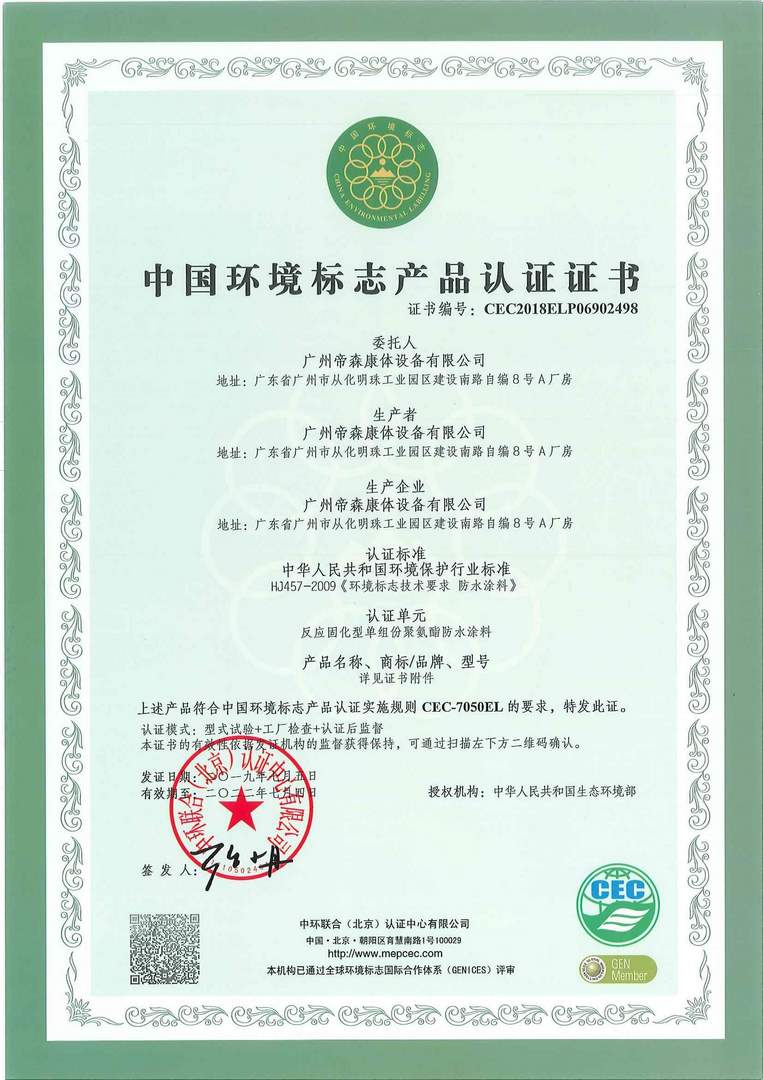

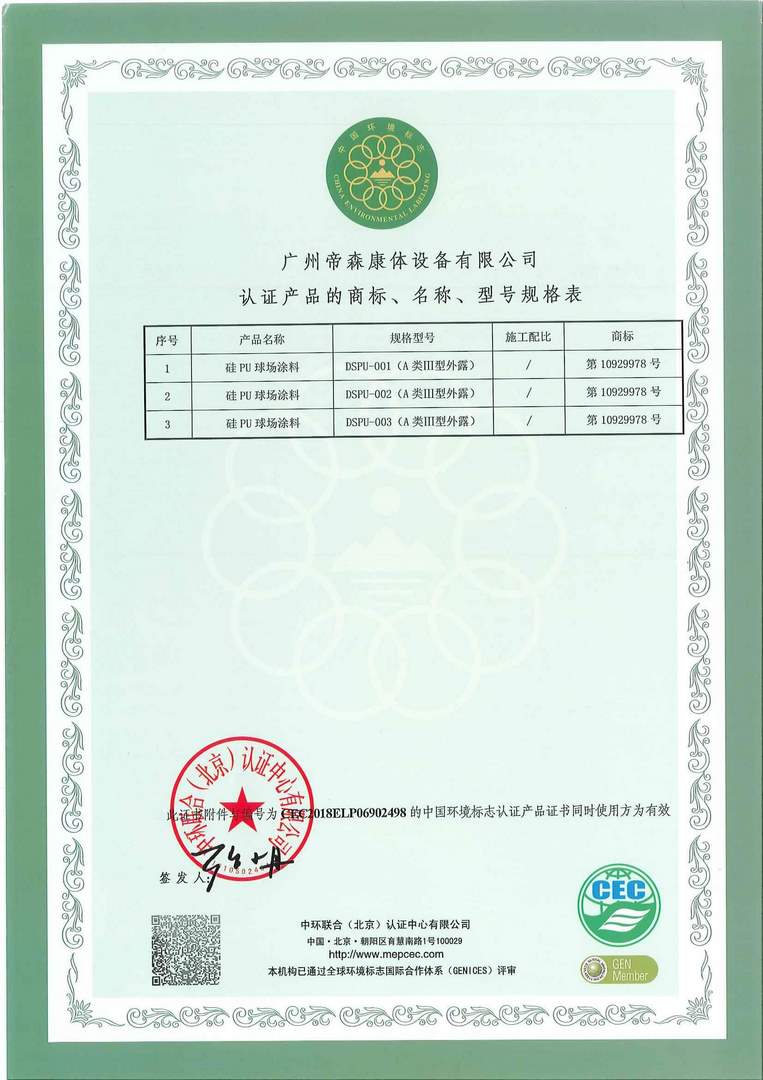

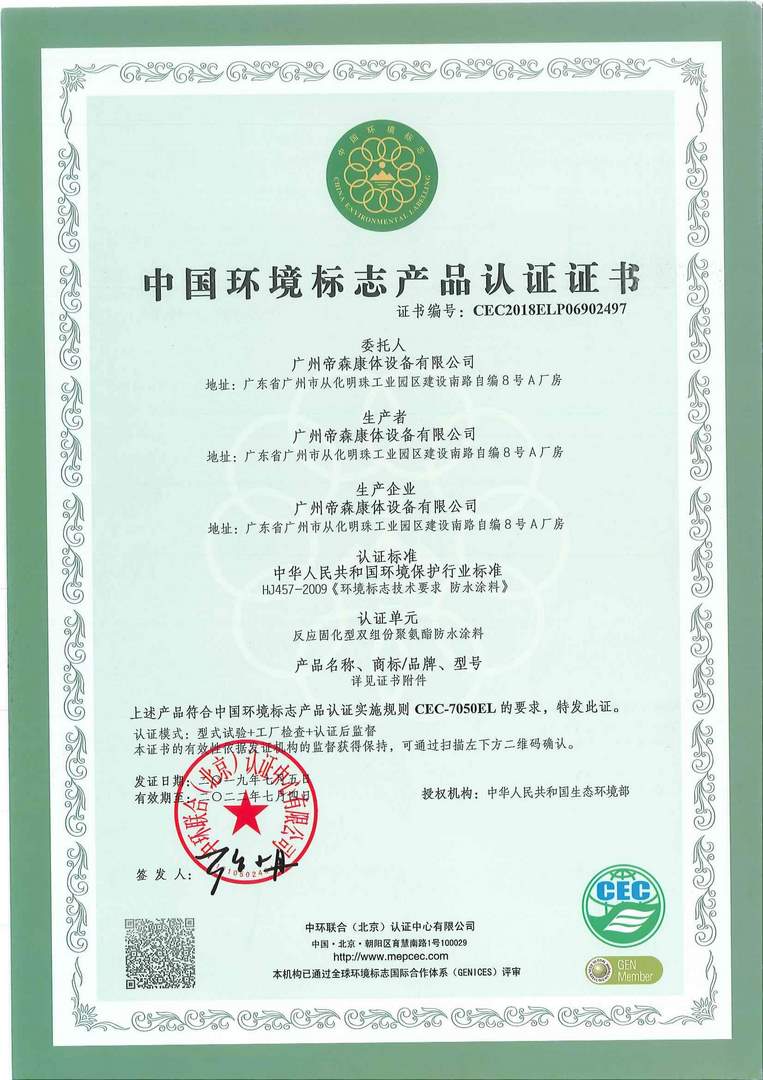

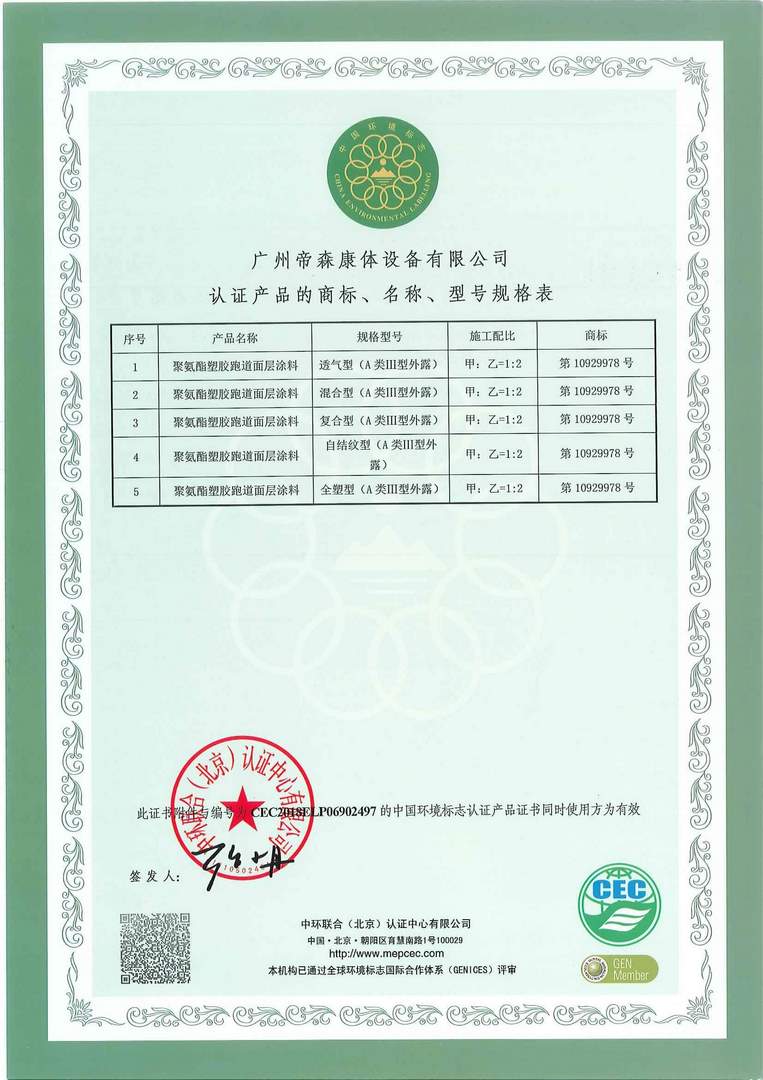

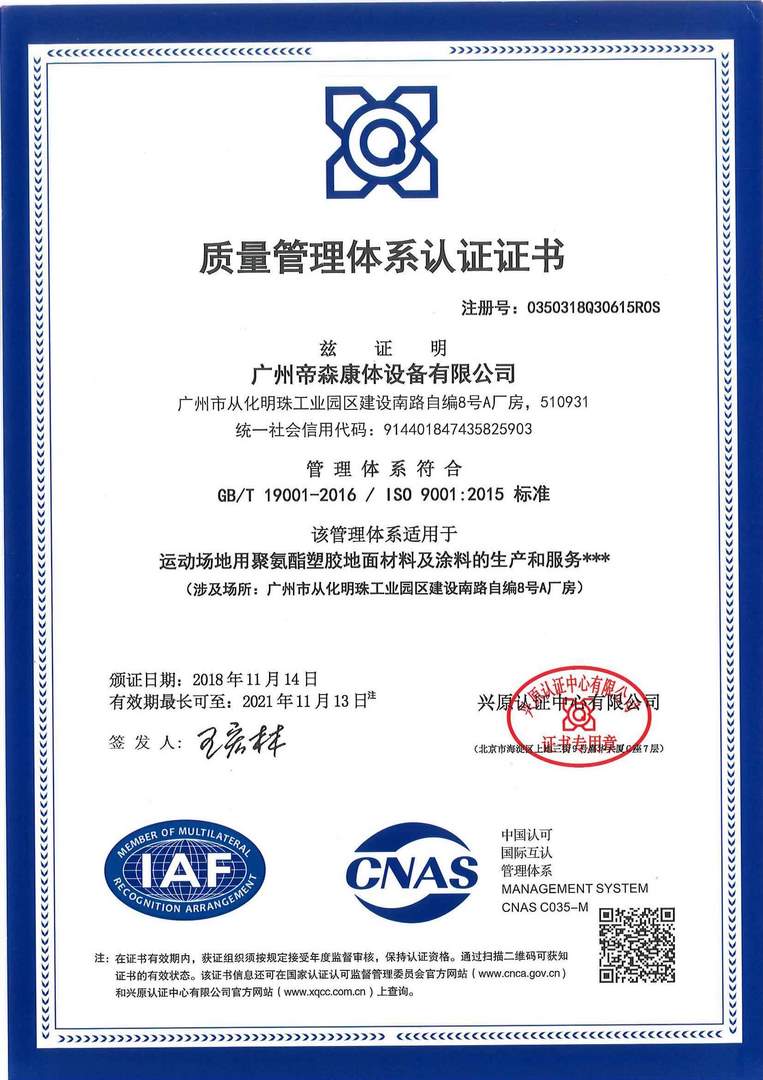

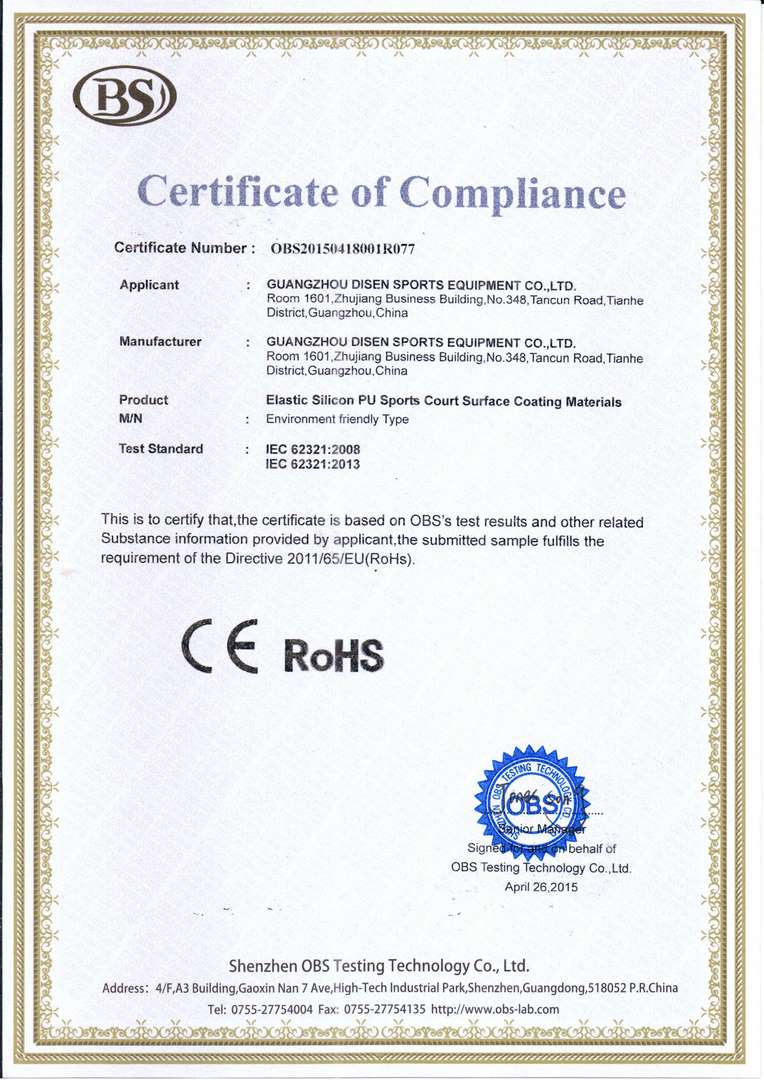

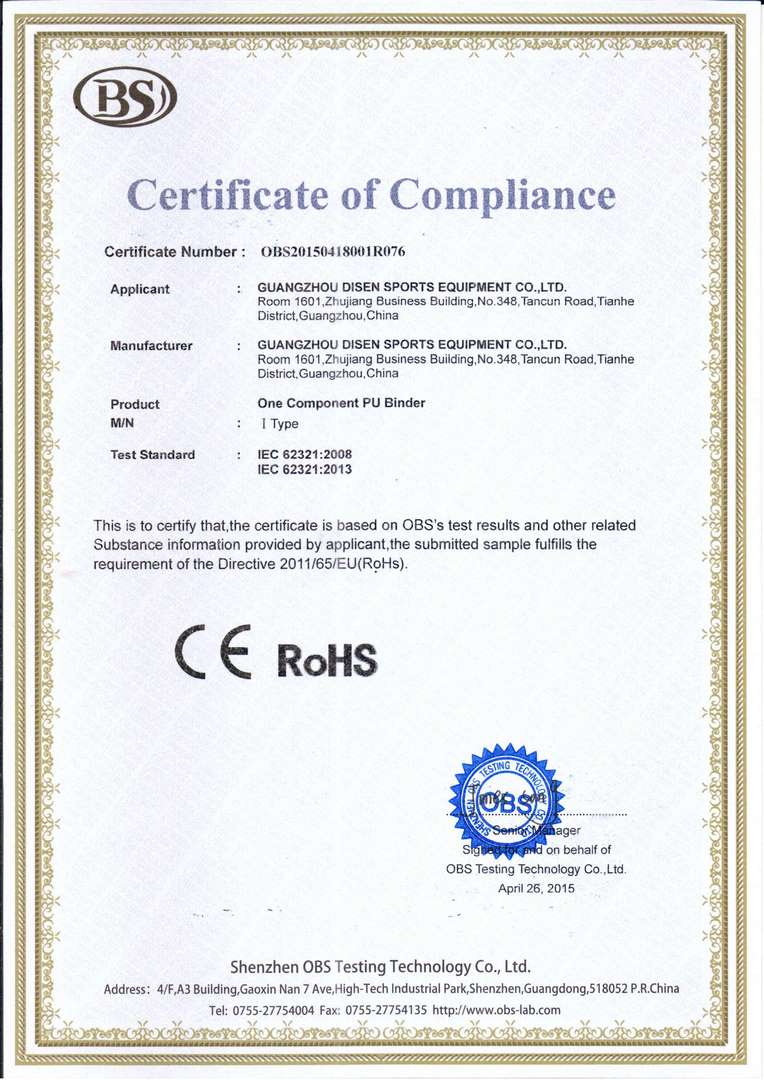

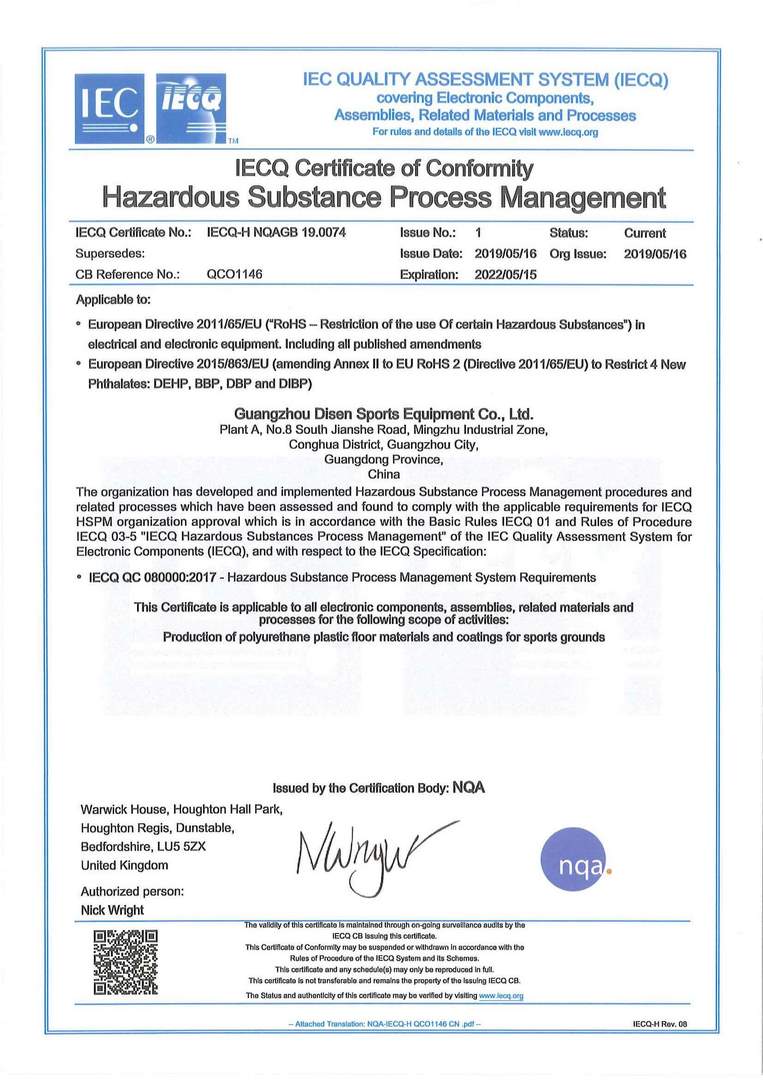

See Our Quality

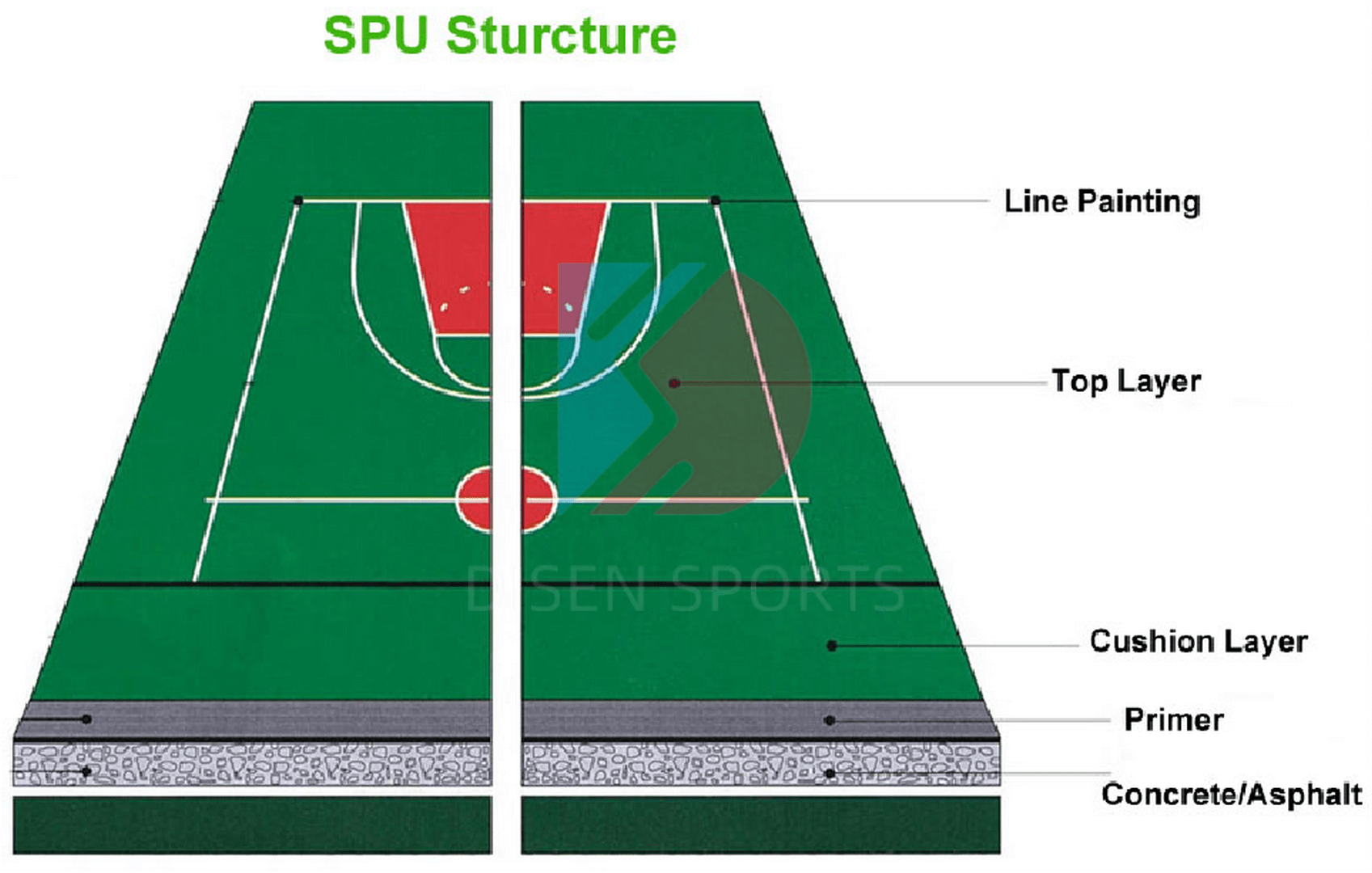

Unit Consumption Chart

| Item | Dosage (kg/m2) | Remark |

|---|---|---|

| Primer | 0.2 | Treat subbase |

| PU Self-leveling Coating | 6 | Cushion layer: 5 mm thickness |

| Drier | 0.05 | Add to No.2 |

| PU Top Coating for Court | 0.3 | Top layer |

| Line Painting | 0.01 | / |

Technical Parameter

| Item | Technical parameters |

|---|---|

| Shock Absorptiong % | 20~50 |

| Vertical Deformation mm | 0.6~3.0 |

| Skid Resistance Value in Dry Test (BPN,20℃) | 80~110 |

| Tensile Strength (Mpa) | ≥0.5 |

| Elongation at break, % | ≥40 |

| Fire Resistance | Ⅰ |

| TVOC mg/m².h | ≤5.0 |

| Oxymethylene mg/m².h | ≤0.4 |

| Benzene mg/m².h | ≤0.1 |

| Toluene, Xylene and ethylbenzene mg/m².h | ≤1.0 |

| Carbon Disulfide mg/m².h | ≤7.0 |

| DPB,BBP,DEHP,DNOP,DINP,DIDP g/kg | ≤1.0 |

| 18 Polycyclic Aromatic Hydrocarbons mg/kg | ≤20 |

| Benzo [a] pyrene mg/kg | ≤1.0 |

| Short-chain Chlorinated Paraffin g/kg | ≤1.5 |

MOCA g/kg | ≤1.0 |

TDI,HDI g/kg | ≤0.2 |

| MDI g/kg | ≤1.0 |

| Pb (mg/kg) | ≤50 |

| Cd (mg/kg) | ≤10 |

| Cr (mg/kg) | ≤10 |

| Hg (mg/kg) | ≤2 |